Rod Pump Controller

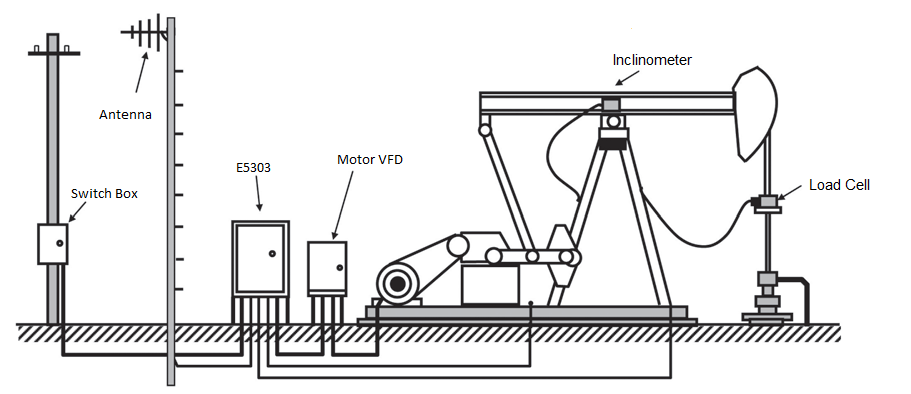

E5303 Rod Pump Controller is designed to control sucker rod pumps for well production optimization.

E5303 Rod Pump Controller is designed to control sucker rod pumps for well production optimization.

Embedded with powerful algorithms, the E5303 computes real time surface and downhole dynamometer cards to best control the starting and stopping of the pump to reduce costs and increase oil production.

E5303 allows operators to collect and analyze data locally and remotely, and retains history data. Ethernet, radio, and cellular communication options allow monitoring at any distance with standard or customized protocols. It is easy to install, easy to configure, and is easy to maintain.

E5303 calculates flow rate without need to install additional flow meter, accounts power consumption, diagnosis real-time failure and prevents malfunctions. E5303 features extra I/O that allows to find a solution for any customer’s needs.

Specifications

- Key Features

- RPC E5303

- Load Cell S920/S923T

- Inclinometer S917

- Position Sensor S918

- Various real-time pump control mode

- Equipment diagnostics and protection in real time

- Fluid production calculation

- Power consumption calculation and efficiency analysis

- Operational history for a long period of time

- Various options of telecommunication

- Extra analog and digital I/O points for different applications

- User-friendly menus

- Remote configuration and update

- Wide operating temperature range

RPC E5303

Main Controller | 400MHz; 32M RAM, 256M flash, 128K NVRAM; 8G SD/MMC card |

Display | LCD, 320×240 |

Keypad | 31 keys |

I/O Interface

| Analog Input (AI) : 8 (4-20mA/0-20mA, resolution 16-bit, accuracy ± 0.2% ) Digital Input (DI) : 4-8 ( level signal) Digital Output: 4-8 (contact signal, contact capacity 250VAC@12A) Analog Output: 2 (4-20mA, resolution 16-bit, accuracy ± 0.2%) Pulse Input (PI) : 2 (pulse signal, frequency 0-1KHz ) |

Communication Interface

| 2 RS232: DB-9M 2 RS485 1 Ethernet: RJ45 2.4G |

Protocols

| RS232/485: Modbus RTU/ASCII, customized Ethernet: Modbus TCP, Modbus RTU via TCP, Modbus RTU via UDP, customized 2.4G: IEEE802.15.4, ZigBee |

Power Supply | Voltage: 120VAC/240VAC or 24VDC Frequency: 47 ~ 63Hz |

PCB | FR-4: protect against Water,H2S and salt air. Lead free. |

Enclosure | Size: 460*403*210 (mm) weight: 8Kg |

Operating Environment | Temperature: -40 ~ + 70ºC Humidity: 5-95% RH |

Load Cell S920 (O-type) & S923T (U-type)

With Rugged design and installed on the polished rod, the load cell can be used to measure the changing of rod load and sends standard 4~20mA signal to the local RTU with high accuracy.

Load Measure Range | 0 ~ 150KN |

Load Measure Accuracy | ± 0.5% F.S. |

Safe Load Limit | 200% F.S. |

Life | 20 million strokes @20 ~ 80% F.S. |

Material | Stainless steel |

Input Resistance | 760Ω |

Output Signal | 4 ~ 20mA |

Operating Voltage | 15 ~ 26VDC |

Compensation Temperature Range | -40 ~ + 80oC |

Operating Temperature Range | -40 ~ + 80oC |

Weight | 2KG |

Inclinometer S917

Inclinometer S917

The inclinometer is usually installed on the beam to measure its tilt angle.

Range | -45° ~ + 45° |

Accuracy | ±0.5% F.S |

Power Supply | 24VDC |

Output Current | 4 ~ 20mA |

Load | < 600Ω |

Operating Temperature | -40 ~ + 70oC |

Operating Humidity | 5 ~ 95% RH, non-condensing |

Size | 132×68×50 (mm) |

Position Sensor S918

Fixed on the base of the rod pump, the position sensor is used to detect the run cycle of the rod pump.

Voltage | 24VDC |

Power Consumption | < 1W |

Operating Temperature | -40 ~ + 70ºC |

Operating Humidity | 5 ~ 95% RH |

Length | 250mm |

Weight | 188g |

Field Application